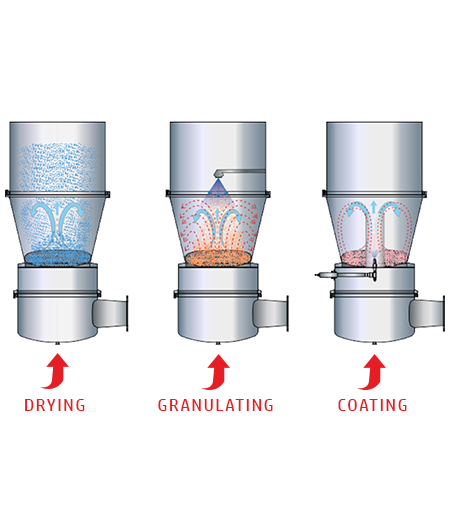

Fluid Bed Systems

Fluid Bed

Lab Scale Production

FBS For Labs

Suitable for R&D, formulation development & small batches

Extends same level of technology on equipment & other systems like:

Provides identical features for production scale equipment for future scalability

This range of systems are suitable for R&D as well as formulation development & exhibit batch manufacture. Extending the same level of technology on the equipment & the other systems such as Air Handling Units, Spray Systems & the controls, it provides excellent parameter & process conditions for future scalability.

Fluid Bed System For Production Fluid Bed Combo Systems

With equipment capacities from 10 kg to about 30 kg, the pilot batch equipment replicates production equipment, with smaller batch processing capabilities.

12 Bar Fluid Bed System

Kevin’s 12 Bar Impact Resistance Fluid Bed Systems are ideally suitable for contained processing of powders as well as high risk powders. With a fully contained design, these equipment provide the highest level of safety & reliability.