The pharmaceutical industry is a dynamic and highly regulated field where product quality, safety, and efficiency are paramount. One critical aspect of pharmaceutical manufacturing is tablet coating, a process that not only enhances the appearance and taste of medications but also affects their performance and effectiveness. While large-scale tablet coating systems have been the go-to choice for high-volume production, medium-scale tablet coating systems are gaining popularity for their ability to strike a balance between efficiency and flexibility. In this article, we’ll explore the key reasons why medium-scale tablet coating is becoming an essential component of pharmaceutical manufacturing.

1. Batch Flexibility: Meeting Variable Demand

One of the primary advantages of medium-scale tablet coating systems is their flexibility in handling varying production requirements. Unlike large-scale systems that are designed for massive production runs, medium-scale equipment allows pharmaceutical companies to efficiently coat moderate quantities of tablets. This flexibility is especially valuable when dealing with products with fluctuating demand levels. It ensures that manufacturing equipment isn’t underutilized during periods of lower demand, optimizing resource allocation.

2. Cost Efficiency: Maximizing Resources

Large-scale tablet coating systems, while capable of high-volume production, often come with substantial capital and operational costs. Medium-scale coating equipment offers a cost-effective alternative. It strikes a balance between production capacity and cost efficiency, minimizing overhead expenses associated with large-scale operations. Pharmaceutical manufacturers can achieve economies of scale without committing to the significant investments required for large-scale equipment.

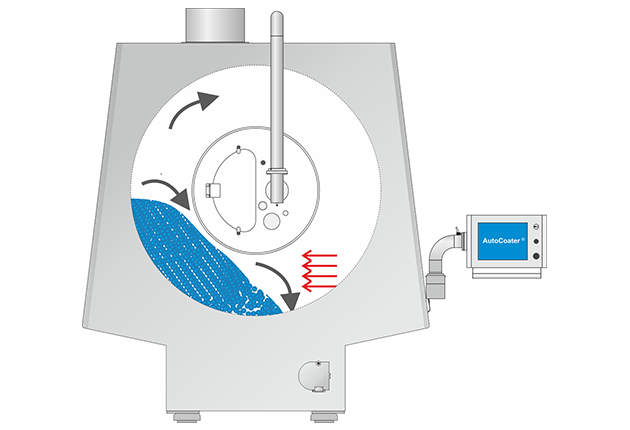

3. Quality Control: Ensuring Consistency

Quality control is a non-negotiable aspect of pharmaceutical manufacturing. Ensuring uniform coating and consistent product quality is essential for meeting regulatory standards and ensuring the safety and efficacy of pharmaceuticals. Medium-scale tablet coating systems provide precise control over critical coating parameters, resulting in uniform coatings across the entire batch. This level of control is vital for pharmaceutical companies striving to meet stringent quality requirements.

4. Product Diversification: Adapting to Varied Needs

Pharmaceutical companies often produce a diverse range of medications, each with distinct coating requirements. Medium-scale tablet coating equipment offers the advantage of efficiently adapting to different coating formulations and materials. This versatility is crucial for companies that manufacture various pharmaceutical products, allowing them to meet diverse market needs.

5. Reduced Material Waste: Sustainability and Efficiency

Efficient coating processes minimize the use of coating materials, reducing waste. This not only contributes to cost savings but also aligns with sustainability goals. Pharmaceutical manufacturers are increasingly focusing on eco-friendly manufacturing practices. Medium-scale tablet coating supports these efforts by optimizing resource utilization.

6. Market Responsiveness: Agility in Production

In today’s dynamic pharmaceutical market, the ability to respond quickly to changing demand is a competitive advantage. Medium-scale tablet coating facilitates timely production adjustments, enabling manufacturers to adapt to market fluctuations and launch products more rapidly. This agility is essential for staying competitive and meeting market demands effectively.

7. Research and Development: Innovation and Testing

Medium-scale tablet coating systems are well-suited for research and development purposes. They enable pharmaceutical companies to test new coating formulations, conduct trials, and refine processes before scaling up to larger production volumes. This supports innovation and ensures that new products meet quality standards from the outset.

8. Regulatory Compliance: Meeting Standards

Medium-scale tablet coating equipment can be designed and operated to comply with stringent regulatory standards and guidelines. This ensures that coated tablets meet the rigorous safety and efficacy requirements set by regulatory authorities. Compliance is non-negotiable in the pharmaceutical industry.