High Shear Mixer Granulators

HSMGs

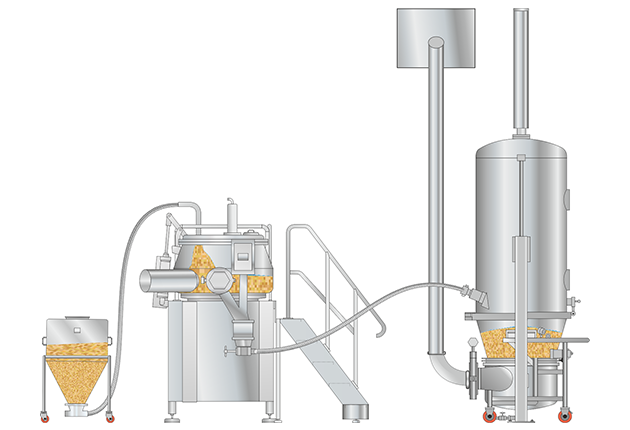

Integrated Transfer Systems

Lab Scale Production

The HSMG 10 offers unmatched flexibility for the high shear mixing & granulation in the laboratory. The equipment can be fitted with a range of processing vessels, right from 1 litre to 15 litres. The HSMG 10 can be provided with a lot of features such as tip speed control, end point detection via real time torque monitoring & jacketed containers for controlled processing.

For research & development

Offers unmatched flexibility in the laboratory

Can be fitted with a range of processing vessels

Interchangeable bowl from 1 litre to 10 litres.

Common Chopper Drive

Can be provided with features such as:

HSMG 25/50/75 & 100

Kevin’s HSMG 25/50/75 & 100 provide the necessary capabilities to scale the product from the laboratory to a pilot batch. Equipment features include all the functions & profiles of larger production equipment. Ease of use & set up are provided. All the Kevin HSMGs are provided with the same efficient mixing impeller design as well as chopper design. The process control software provides similar functionality as the larger equipment.

High Volume Production

High Shear Mixing Systems, with capacities up to 2000 Litre are offered for high volume production. With features that offer the highest amount of safety & controls, the equipment is easy to operate & control. The high volume production equipment features a lot of features & automation for easy & automatic handling of materials as well as loading & unloading under closed conditions. The equipment provides very high level of operational stability & ease of use for continuous production. Capacity up to 2000 litres.

Features & automation for: